At Genpak, we understand that every food application requires a specific material to enhance the consumer experience. We acknowledge how important it is to provide detailed information on the materials used to engineer our quality food packaging containers.

Polypropylene

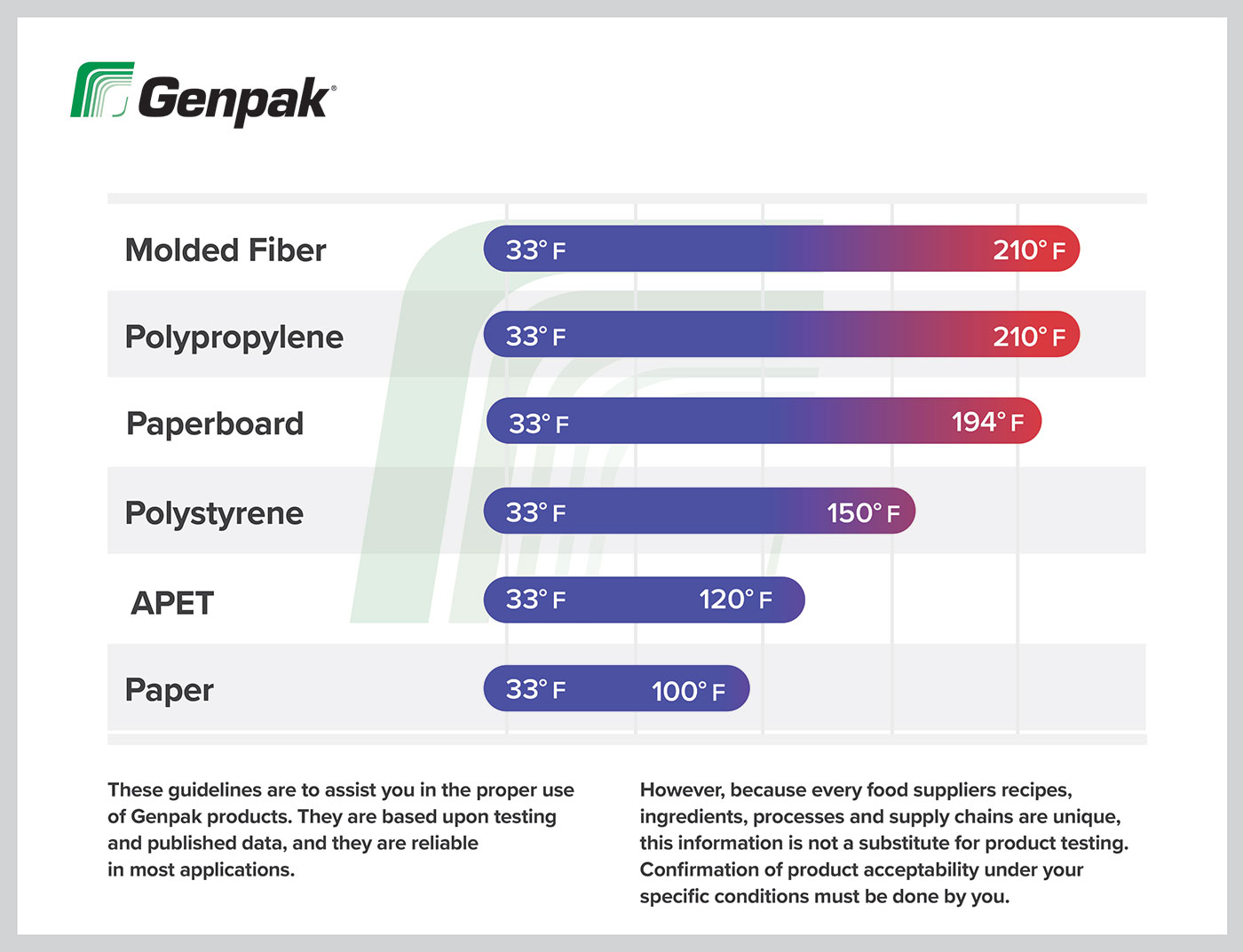

Polypropylene (PP) is a hard plastic material best used for rigid packaging. Our polypropylene products are durable and made to withstand a heat tolerance of up to 210°F making them a great option for microwave-safe food packaging.

Material Benefits:

- Stackable

- Leak Resistant

- Microwave Safe

- Dishwasher Safe

- Curbside Recyclable

- Home Reusable

- Made in the U.S.A

Compostable

Harvest® Fiber

Harvest® Fiber is manufactured using renewable resources, produced from nonfood sourced, fiber-based materials that are 100% annually renewable. The fiber material is bagasse, which is a byproduct of the sugar industry. The containers are BPI Certified Commercially Compostable and USDA BioPreferred.

Material Benefits:

- Meets ASTM D6868 composting standards for commercially managed facilities

- GMO Free

- No added PFAS

- Certified USDA Biobased

- Excellent Grease & Oil Resistance

- Microwave Safe

- Stackable (designed to travel well)

- Suitable for Hot and Cold Foods

- Moisture Resistant

*USDA label assures that the product contains renewable biological ingredients. Managed lands are made up of sections of trees organized by age. Only one section is cut at a time, the most mature of the group. That section is then planted with seedlings to replace harvested trees to continue the growing cycle. Derived from plants and other renewable agricultural, marine, and forestry materials. Provide an alternative to conventional petroleum derived products. Products do not include food, animal feed, or fuel.

Harvest Paper

Genpak Harvest Paper is produced using renewable fiber originating from forests managed with Sustainable Forestry Practices. All our Harvest Paper product configurations are engineered to be lightweight while providing maximum stability and durability by utilizing box pleats, concave surface areas, and rolled rims.

Material Benefits:

- Sustainable – Certified SFI® sourced material

- Prop 65 compliant

- Compostable in commercially managed facilities

- Made in the U.S.A.

Paperboard (PB)

Paperboard is a thick paper-based material that can be single- or multi-ply. Paperboard can be easily cut and formed to make light but sturdy packaging. Our paperboard material is sourced only from SFI® certified forests, making it a functional and sustainable packaging solution.

Material Benefits:

- PFAS free

- Prop 65 compliant

- Oil & grease resistant

- Sustainable – Certified SFI® sourced material

- Made in the Canada

*USDA label assures that the product contains renewable biological ingredients. Managed lands are made up of sections of trees organized by age. Only one section is cut at a time, the most mature of the group. That section is then planted with seedlings to replace harvested trees to continue the growing cycle. Derived from plants and other renewable agricultural, marine, and forestry materials. Provide an alternative to conventional petroleum derived products. Products do not include food, animal feed, or fuel.

PET – Polyethylene Terephthalate

P.E.T. plastic or APET is a crystal-clear plastic material that is an excellent choice when displaying food items. APET products carry the #1 recycling icon and plastic identification symbol and are the most common type of curb-side recyclable plastic. APET may be used in cold applications and will hold up in automated fill/seal process lines. We manufacture all APET items with up to 30% post-consumer recycled content making it very attractive to customers looking for a “green” profile in their food packaging.

Material Benefits:

- Produced with up to 30% post-consumer recycled material

- Excellent water vapor barrier for extended shelf life

- Curbside recyclable

- Home Reusable

- Made in the U.S.A.

Polystyrene

Polystyrene (PS) is a versatile plastic that when foamed, forms a lightweight but sturdy material that can be made into a multitude of shapes and configurations. Manufacturing our PS products requires little energy and water during the production process.

Material Benefits:

- Lightweight

- Great Insulation

- Keeps Hot foods Hot, Cold foods Cold

- Uses Low Energy and Water in the Manufacturing Process

- Made in the USA

- Recyclable (check your local municipality)