The three R’s of sustainability include Reduce, Reuse and Recycle. We have all seen evidence of source reduction with plastic water bottles. They have consistently gotten thinner and lighter. The average P.E.T. water bottle has gone from 18.9 grams to 12.7 grams. That decrease alone saved over 1 billion pounds of P.E.T. resin. Well done bottling industry!

The three R’s of sustainability include Reduce, Reuse and Recycle. We have all seen evidence of source reduction with plastic water bottles. They have consistently gotten thinner and lighter. The average P.E.T. water bottle has gone from 18.9 grams to 12.7 grams. That decrease alone saved over 1 billion pounds of P.E.T. resin. Well done bottling industry!

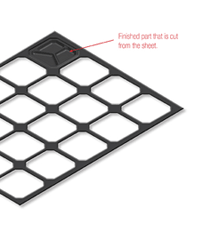

We firmly believe source reduction should be practiced. But, unlike our competitors, we don’t just lightweight products for the sake of light weighting. We do not believe our customers want to sacrifice functionality for a lighter and cheaper part. We therefore achieve source reduction via other means such as product design and R&D work. A great example is Genpak’s exclusive textured, polypropylene material used to manufacture some of our products. These products are on average, 24% lighter than like, injection molded polypropylene products. This textured material allows us to make a lighter part without any compromise to product functionality.

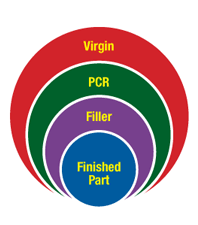

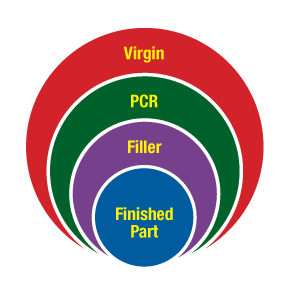

Another source reduction technique Genpak utilizes is the use of natural fillers to replace virgin resin. Our Harvest Pro line is an excellent example that. A full 40% of each product’s part weight is comprised of a natural mineral filler. So if a part weighs 10 grams, 4 grams of it, is a natural mineral while the other 6 grams is the standard raw material. This is an excellent technique of source reduction that both saves raw materials and utilizes a natural filler all while maintaining product functionality and integrity.